Product material highlights

The company is located in Qingbaijiang District, Chengdu, specializing in the development and manufacture of corrosion-resistant, wear-resistant pumps and mixers for nearly 30 years. The company has advanced resin sand casting, mechanical processing, large-capacity intermediate frequency furnace melting technology and equipment, and advanced comprehensive performance testing platform. The company has passed the ISO9001:2015 quality management system certification, ISO14001:2015 environmental management system certification, ISO 45001:2018 occupational health and safety management system certification; The design and development, casting, cold working, assembly, testing and testing of its products are independently completed by the company, there is a strong machine supporting production and quality assurance capabilities. Products are widely used in chemical, smelting, mining, electric power, coal, paper, pharmaceutical, energy conservation and environmental protection, new energy materials and other industries, and enjoy a high reputation in the industry.

1. main products:

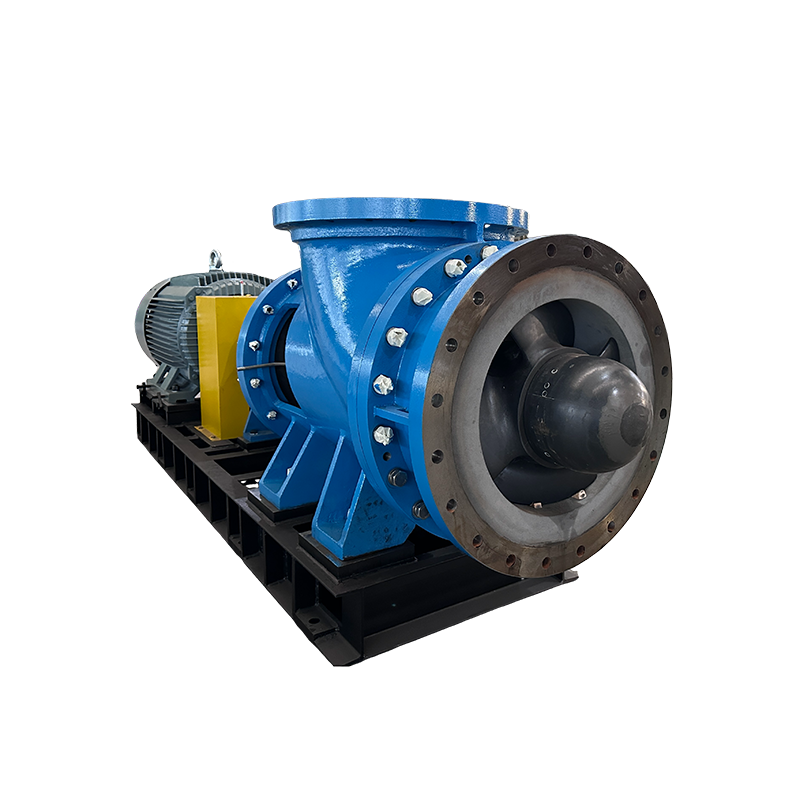

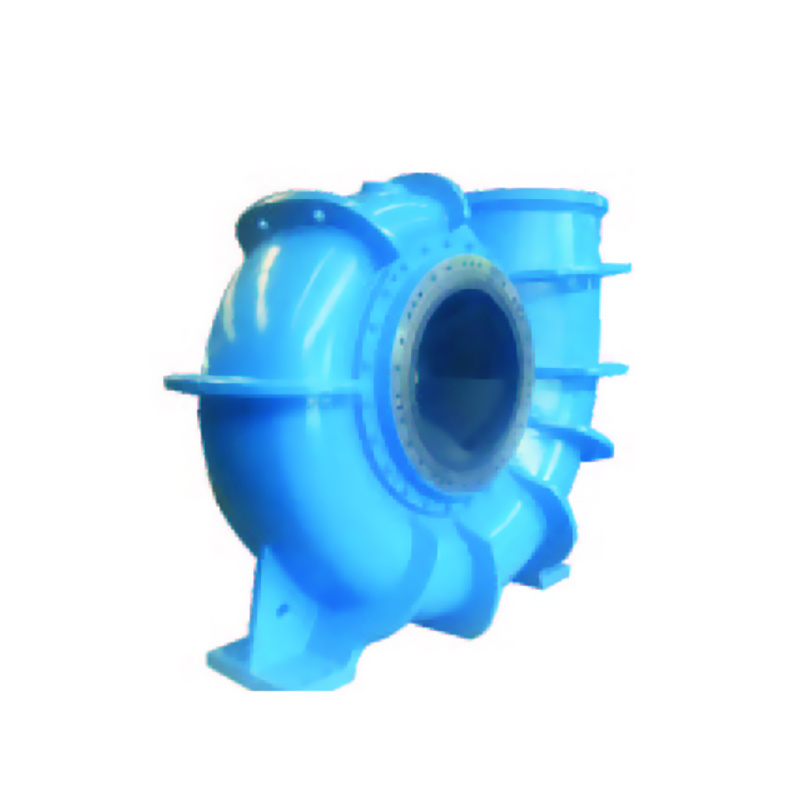

DCS Series New Type Carbon Fiber Composite Centrifugal Pump

ZWT series new carbon fiber composite axial flow pump

ZJ(G)T Series New Type Carbon Fiber Composite Slurry Pump

HLT series new carbon fiber composite mixed flow pump

TXL series new carbon fiber composite material liquid pump

WD/WDL Series Corrosion and Wear Resistant Centrifugal Pumps

CZ/ZA/ZAL series chemical pump process pump

ZJ/ZJL series slurry pump

ZW/ZWL series slurry pump

YYTL series desulfurization pump

YLSB high temperature concentrated sulfuric acid pump/energy saving agitator

2. is committed to revolutionizing the industry:

The use of impurity pump is mostly based on physical and chemical conditions with ore as raw material. The transported materials contain a large number of solid particles, and most of the chemical conditions are not only high temperature but also various acid and alkali corrosion, so the over-flow parts of the pump and the life of the seal are very short. The late service output value of a whole pump is basically more than 10 times the price of the product itself. Company deep plowing impurity pump, long-term commitment to the research and development of wear-resistant and corrosion-resistant materials. The production organization form of the whole industrial chain is a personalized customized service for each customer.

1. New carbon fiber composite pump:

In 2012, the company's non-metal expert workstation began to develop a new type of carbon fiber composite pump. In 2013, it obtained a national invention patent. The performance of the product has been used in titanium dioxide, phosphorus chemical industry, zinc hydrometallurgy, flue gas desulfurization and chlor-alkali industry for nearly 10 years. The application has been accurately verified, and its service life is more than 5 times that of the metal pump.

The new carbon fiber composite material is corrosion-resistant, wear-resistant and high-temperature resistant, and does not contain metal elements. It provides stable quality assurance for the special requirements of the new energy battery precursor industry. It has been widely used in iron phosphate and carbonic acid carp devices. The technical advantages of the pump are as follows:

Advantage one: long service life

New type of carbon fiber composite material series pump: its main component: carbon fiber composite material. The tensile strength is 55 ~ 75MPa; the wear-resistant hard phase volume ratio is ≥ 70%; the service life is 5~10 times that of the metal pump.

Advantage two: high pump efficiency

The molding process is advanced, and the same high-efficiency twisted blades as the metal pump can be used. The efficiency of the new pump is generally more than 10% higher than that of the engineering plastic pump with straight blades. Because of the long life of the over-current components and the long running time of the pump in the high efficiency range, the weighted average efficiency of the carbon fiber pump in the life cycle is 8%-10% higher than that of the metal pump.

Advantage three: machine seal long service life

The impeller metal mold is formed and the blades are hydraulically balanced to ensure that the impeller runs without radial vibration caused by additional radial force. The rotor shall be subjected to 2.5-level dynamic balance experiments according to API610 standard to ensure smooth operation of the impeller. The impeller is resistant to wear to avoid unbalanced balanced operation of the impeller caused by wear. The short cantilever ratio design is adopted to further ensure smooth operation of the impeller.

Advantage four: no metal ion pollution

Carbon fiber composite material series pump and media contact parts including machine seal, over-flow parts, no metal materials, no electrochemical corrosion, put an end to metal ions on the product pollution, to ensure product purity requirements.

Advantage five: strong corrosion resistance

New carbon fiber composite pump acid resistance: resistance to hydrochloric acid, fluosilicic acid, hydrofluoric acid, phosphoric acid, dilute H2SO4 and other corrosive media.

New carbon fiber composite material series: PH≥ 0 can withstand 160 ℃ ;55% H2SO4 or 85% H3PO4 can withstand 120 ℃.

Advantage six: the use of low maintenance costs

The new carbon fiber composite series pump adopts a rear door opening structure, the motor and the pump head adopt an intermediate section and a long diaphragm coupling, the pump body and the motor do not need to be disassembled when replacing parts, and the coupling does not need to be aligned twice after reassembly, which is convenient for overhaul and maintenance.

Advantage seven: strong adaptability

The high efficiency area of the pump is wide, which can meet the requirements of users in a wider range. In addition, we adopt the method of increasing the speed to use the pump, which has very good selectability and can ensure the selection of operating points for most users.

The pump body and impeller adopt wide flow passage design, which makes the pump adaptable to working conditions and has strong passing ability. It is especially suitable for medium with high solid content and large particles.

Advantage eight: high reliability

The shaft is designed with low cantilever ratio, and heavy cylindrical roller bearings and paired double row angular contact ball bearings are installed back to back, which can not only bear large radial load and axial load, but also make the pump more stable in variable working conditions.

All impellers are subject to 6.3-stage static balance test, and the whole rotor is subject to 2.5-stage dynamic balance test according to API610 standard.

The pump shaft adopts a dry structure design. Under normal use conditions, the pump shaft does not contact the conveyed medium, and is not subject to corrosion by the medium, ensuring the service life of the shaft.

Pump body, impeller mold for the overall three-dimensional CNC machining; other parts for CNC machining, to ensure manufacturing accuracy, so that the whole pump in the operation process of smooth operation, vibration, improve the service life of the machine seal and bearings.

Advantage nine: high generalization

Except for a few parts such as pump body and impeller, the rest adopt modular design to realize the standardization of parts. The bearing body parts and sealing parts of coaxial system can be interchanged to facilitate the mass production of pumps.

Advantage 10: Other

The surface finish of the impeller and pump body is high, and the material is not easy to bond and scale on its surface.

During the neutralization process, the reaction is uneven or insufficient, and the residual sulfuric acid or corrosive medium will corrode the metal pump, while the carbon fiber composite pump will not happen.

2. Casting materials with excellent wear resistance:

The company has developed the hardest casting metal material on the earth N12S for the slurry pump flow components used in mining, directly breaking the traditional high chromium cast iron life ceiling, about 3 times the life can greatly extend the maintenance cycle of mineral processing equipment, improve the start-up rate. Due to the low price of the bid market environment limits the promotion of N12S products, when China and the world to further integrate N12S will no longer be just the company's technical reserves.

company independent research and development of materials:

Non-metallic materials: TQ3, TQ4

Metal materials: A27W, N12S, TH3

DCS Series New Type Carbon Fiber Composite Centrifugal Pump

ZWT series new carbon fiber composite axial flow pump

ZJ(G)T Series New Type Carbon Fiber Composite Slurry Pump

HLT series new carbon fiber composite mixed flow pump

TXL series vertical carbon fiber composite centrifugal pump