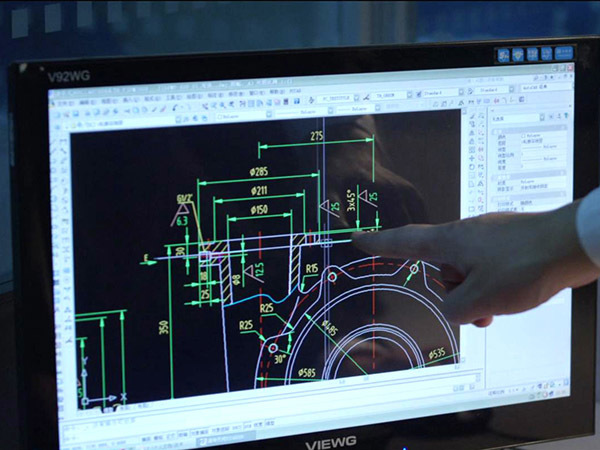

R & D and improvement

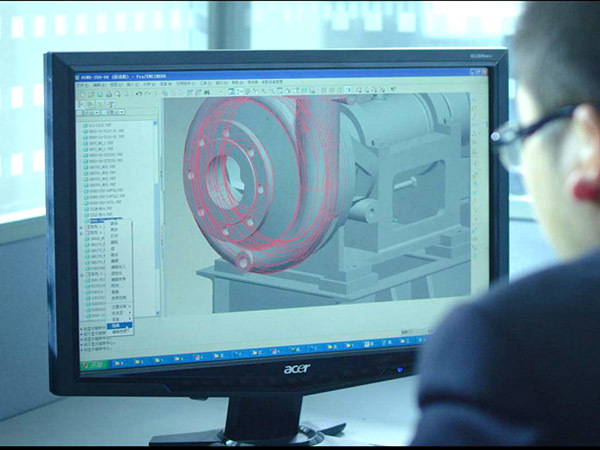

The company has an advanced design platform, using three-dimensional, flow field analysis software for product structure and flow state analysis; the company has hydraulic machinery, casting smelting, mechanical processing, heat treatment and other types of professional and technical personnel, with a number of patented technology; the company is a member of the Phosphorus and Sulfur Industry Association, a key test platform of Xihua University, a joint base of production and learning of Xihua University, and has been awarded by Chengdu Industrial Design Center, Chengdu High-tech Enterprise, Qingbaijiang Taxpayer and other qualifications and honors.

1. Technical force resources:

It has specialized technical and research departments, with 19 senior technical personnel and 6 design and development personnel. Close cooperation with Xihua University and Beijing Steel Research Institute. It is a member of the Phosphorus and Sulfur Industry Association, a key test platform of Xihua University, a joint base of production and learning of Xihua University, and experts and engineers in various industries. It has successfully integrated cutting-edge technologies such as optimized structural design and internal flow field analysis into products, and can provide every customer with the most practical products and perfect technical solutions.

2. Development cycle:

Product drawings timely update, new product development every year.

3. Results and application:

More than 20 years of operation exploration and accumulation, technology and research and development continue to optimize and upgrade, to create a high-end professional team, the company has a special capital investment, so that the research and development of new products have been supported and guaranteed.

New carbon fiber composite series pump

In 2012, the company's non-metallic expert workstation began to develop a new type of carbon fiber composite pump. In 2013, it obtained a national invention patent, which has been accurately verified in the wet zinc smelting, titanium dioxide, phosphorus chemical industry, and flue gas desulfurization industries in the past ten years. It has been widely used in iron phosphate and lithium carbonate devices. Its highlights are as follows:

1. Does not contain metal elements:

The components in contact with the medium are completely free of metal materials, eliminating metal ion pollution and providing stable quality assurance for the special requirements of the new energy battery precursor industry.

2. Corrosion resistance:

Acid resistance: resistance to caustic soda, hydrochloric acid, fluosilicic acid, hydrofluoric acid, nitric acid, phosphoric acid, dilute H2SO4 and other corrosive medium, almost all immune acid and alkali corrosion.

3. Temperature resistance:

PH ≥ 0 can withstand 160 ℃ ;55% H2SO4 or 85% H3PO4 can withstand 120 ℃. Tolerant temperature range does not soften, no engineering plastic pump with the temperature rise caused by the soft seal leakage and over-current wear problems.

4. Wear resistance:

The particle size is less than 20 mesh, the use performance is excellent within 50% of the solid, and the corrosion resistance, wear resistance and high temperature resistance are exactly verified in the practical application of titanium dioxide, phosphorus chemical industry, zinc hydrometallurgy, flue gas desulfurization and coal powder utilization for nearly ten years. Its service life is more than 5-10 times that of metal pumps.

5. Significant energy saving:

Metal mold, the actual product and the theoretical hydraulic curve completely fit, smooth operation, small vibration, strong anti-cavitation ability, excellent performance in energy saving and consumption reduction, one is the new pump efficiency, the second is the carbon fiber pump corrosion-resistant wear-resistant, long-term operation in high-efficiency conditions, the life cycle weighted average efficiency is higher.

6. Machine seal:

Unique sealing structure, container type mechanical seal, the site is clean and environmentally friendly, and the parts in contact with the medium are also non-metallic materials, no metal materials, to prevent metal ion pollution.

7. Fast maintenance:

The structure is simple, the diaphragm coupling is connected, the maintenance is simple and the time is short, and the work efficiency is effectively improved.

The characteristics of the above pumps are favored in the field of new energy power batteries. At the beginning of this year, Yunnan Yuntianhua's 100000-ton iron phosphate project all adopted the company's carbon fiber composite pump as the main process pump, with a purchase amount of tens of millions. The consensus that the company will directly use carbon fiber composite pumps for the 200000-ton iron phosphate project in the later period has also been reached. At present, the total investment scale of iron phosphate and lithium salt projects that are or will be launched in China alone is no less than 100 billion.

Sulfuric acid titanium dioxide industry waste acid concentration pump for decades has been the industry's pain point. As the medium is high temperature dilute sulfuric acid corrosion is extremely strong, a large number of ferrous sulfate crystals and cause particle wear, the working condition of engineering plastic pump is not high temperature erosion, high silicon cast iron pump is hard and brittle easy to crack, the maintenance cycle is difficult to exceed 2 months. Since October this year, the company's carbon fiber composite axial flow pump has been tested in a waste acid concentration plant in Panzhihua. The whole industry is looking forward to the application effect of this pump. Due to the complex operating conditions industry pain points resulting in the station pump compared to other pumps of the same model is several times higher prices, is an important source of future profit growth for the company.

Wet phosphoric acid impurity removal refined industrial grade food grade phosphoric acid on the pump requirements are extremely high, on the one hand to prevent metal ions from re-entering the product, on the other hand, the process of special organic solvents are harmful to most polymer materials, so the device pump has long been a graphite pump factory in Jiangsu completely monopolized. At the beginning of this year, the axial flow pump impeller of the company's carbon fiber composite pump was successfully tried out in the refined phosphoric acid plant of a listed phosphorus chemical company in Hubei, and the trial of the complete set of pumps has also entered the installation and commissioning stage. Because the graphite pump has a fatal weakness is its very low efficiency, there are already a number of phosphoric acid plant engineers and the company to discuss the carbon fiber composite material pump can bring them how much energy-saving benefits in the future. I believe that next year the company will be able to share the market dividends formed by the pre-monopoly of the refined phosphoric acid pump, because the monopoly naturally has a high monopoly price.

Research and development of casting materials with excellent wear resistance

The company has developed the hardest casting metal material on the earth N12S for the slurry pump flow components used in mining, directly breaking the traditional high chromium cast iron life ceiling, about 3 times the life can greatly extend the maintenance cycle of mineral processing equipment, improve the start-up rate. Due to the low price of the bid market environment limits the promotion of N12S products, when China and the world to further integrate N12S will no longer be just the company's technical reserves.

A polyphenylene sulfide and silicon carbide composite material, preparation process and its use.

Fiber-containing silicon carbide, resin composite material and method for making pump components

Production method of 2507 stainless steel pump casting

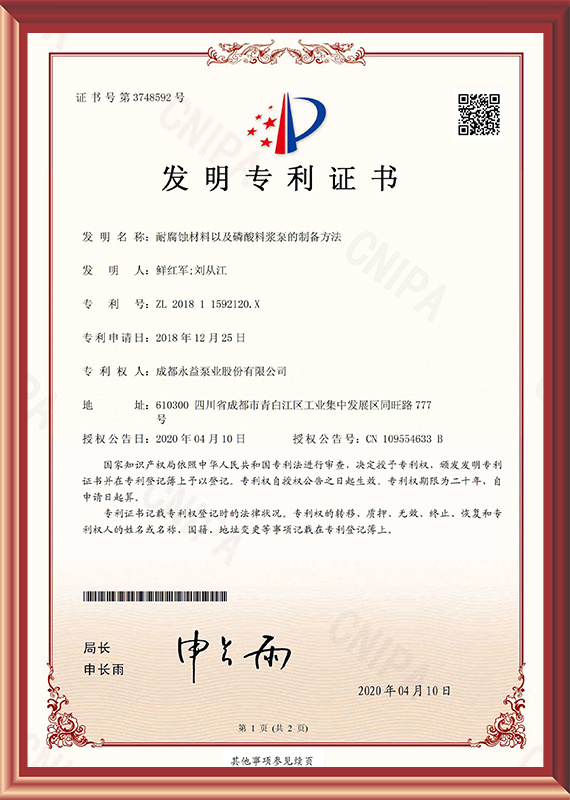

Corrosion resistant material and preparation method of phosphoric acid slurry pump